Lavatory syphon cisterns - how they work

A syphon type lavatory cisterns flush is more reliable than the older Burlington bell style flush and can be used with high level, low level and close coupling cistern positions.

The cisterns itself are usually made from plastic or ceramic.

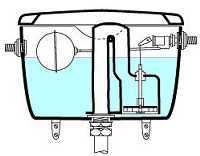

The syphon is basically an inverted U within the cistern with the bend above the level of the water.

The syphon is basically an inverted U within the cistern with the bend above the level of the water.

One end of the syphon is coupled to the down pipe connecting the cistern to the pan, the other end of the syphon is chamber the bottom of the cistern

Within the chamber is a perforated disc covered by a flexible material (the flap valve) which is attached to a vertical rod attached to the lever mechanism.

When the perforated disc is lifted up within the syphon by the vertical rod being operated by either by a handle or chain action, the water above the disc/flap is forced over the top of the inverted U and flows down in the pipe to the pan.

When the perforated disc is lifted up within the syphon by the vertical rod being operated by either by a handle or chain action, the water above the disc/flap is forced over the top of the inverted U and flows down in the pipe to the pan.

Once the water starts to flow down the down pipe, the syphon effect created draws the rest of the water out of the cistern to flush the lavatory.

The syphon continues to work until air is drawn into the cistern.

After the cistern has been emptied, water begins to refill the cistern and a weight on the perforated disc causes it to drop back down. As the level of water rises in the cistern, the flexible material covering the perforated disc allows water to enter that end of the syphon.

The water level in the syphon remains below the bend (so it cannot flow down to the pan) and is ready to initiate the syphon the next time that the handle or chain is operated.

Half flush cisterns.

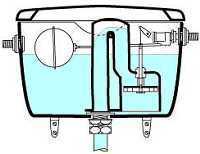

To economise on the use of water, some modern cisterns have both a half and a full flush; the full flush is operated by pushing the handle (or pulling the chain) and holding it until the flush is complete, a half flush is obtained by operating the handle and releasing it as soon as the flush starts.

These 'half flush' cisterns usually incorporate a large hole in the syphon half way down the normal water level. When the handle is pushed and released, the syphon operates until the water level drops to the hole and air enters the syphon. However, when the handle is pushed down and held, the hole is sealed by the raised disc within the syphon and the water flows until the level drops to the bottom of the syphon and air enters from the bottom.

The weaknesses of direct action syphon cisterns include:

- The linkage between the rod which raises the disc can become detached from the handle or chain rocker.

- Setting the correct water level - if the water level is too low, there will be insufficient water above the disc to start the operation of the syphon. However, once the correct water level has been set, this won't be a problem unless something does wrong with the material on the perforated disc (see below).

- The flap valve (i.e. the flexible covering on the perforated disc) will become worn after years of operation - this will prevent enough water being raised over the top of the inverted U when the handle is operated as some of the water above the disc will flow back through the worn flap and the cistern will not flush. However, the flexible flap material can be replaced as low cost and this will return the cistern's operation to 100% efficiency. Details for changing the flap material are given on this page.

- One problem with half flush cisterns is that people don't operate them correctly. Where people are unfamiliar with half flush cisterns, they will just push the handle and release it whether they need a full or half flush. Education is the answer, a lot of half flush cisterns come with a label to attach to the cistern - it just says, something like 'hold down handle for full flush', these labels may be considered unsightly but are worth fitting to the cistern.